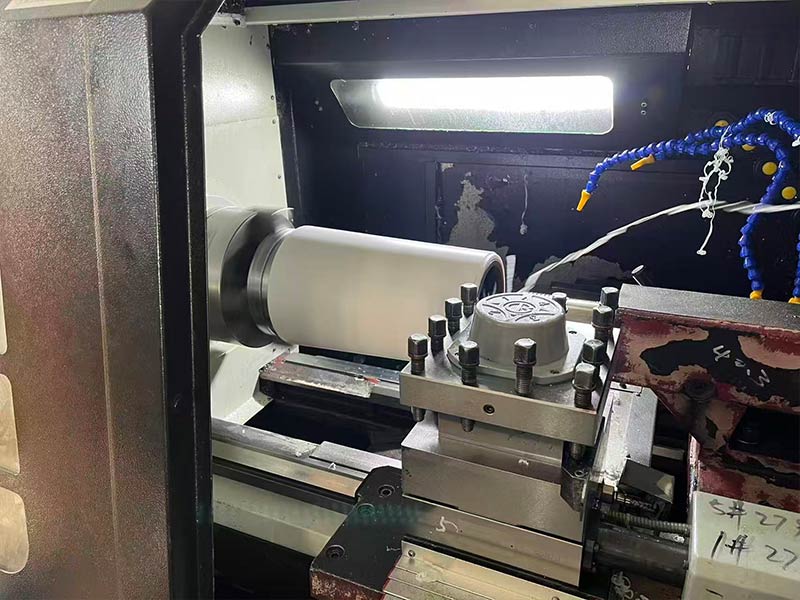

RESTA owns a indipendent plug valve factory with strong scale advantages and professional production capabilities. Covering an area of 15,000 square meters, our intelligent production base is equipped with 8 advanced automated production lines and 50+ sets of high-precision CNC machining equipment, supported by a team of 80+ professionals including R&D engineers and skilled technicians. We specialize in two core product series: FEP/PFA/PTFE/PEEK lined plug valves and premium special alloy plug valves. Our alloy range is comprehensive, including duplex steel (4A/5A/6A/1A/1B), titanium (Gr1/Gr2/Gr5), nickel (Ni200/Ni201/Monel 400), zirconium (Zr702/Zr705), Hastelloy (HC-276/HC-22/HC-4) and UB6 alloy—all selected for extreme corrosive resistance. With an annual output of 30,000+ sets, we ensure stable bulk supply while maintaining strict quality control through a 22-step full-process inspection system.

Engineered to solve severe corrosion challenges, our corrosion-resistant plug valves are widely trusted across the global petrochemical, chemical processing, natural gas transmission and semiconductor manufacturing industries. In petrochemical plants, they excel in handling high-sulfur fluids and acidic waste; in chemical processing, they reliably control reactive intermediates; in natural gas systems, they withstand sour gas corrosion; and in semiconductor fabs, they ensure contamination-free ultra-pure chemical handling. Strictly compliant with API 6D, ASME, ISO 9001, CE and stringent NACE MR0175 standards, our products guarantee long-term stable operation with a 99.9% qualification rate. Available in manual, pneumatic and electric drive modes (DN15–DN600), our valves have served 500+ global clients and established long-term partnerships with major enterprises in Europe, North America and the Middle East, becoming the preferred choice for critical corrosive medium applications.