Resta follows ISO 9001:2000, API Spec. Q1< Specification for Quality Programs for the Petroleum and Natural Gas Industry>, (Seventh Edition) and API Spec. 6D.

Before the manufacturing, our engineer will discuss with the production manager on the valve design and workmanship. In this way we ensure that valves will be made in full compliance with the orders, assuring no serious problem will happen due to the design error.

For every order, our inspector will do raw material inspection, NDT, dimension inspection, pressure test and final inspection in accordance with international standards.

PERFORMED ON 100% OF VALVES

- Visual & dimensional inspection of valve components

- Visual & dimensional inspection of assembled valves

- High pressure hydraulic body and seat test

- Low pressure air seat test

PERFORMED AS SPOT CHECK OR ON CUSTOMER REQUEST

- Dye Penetrate test (DP)

- Magnetic Particle test (MP)

- Ultrasonic test (UT)

- Positive Material Identification (PMI)

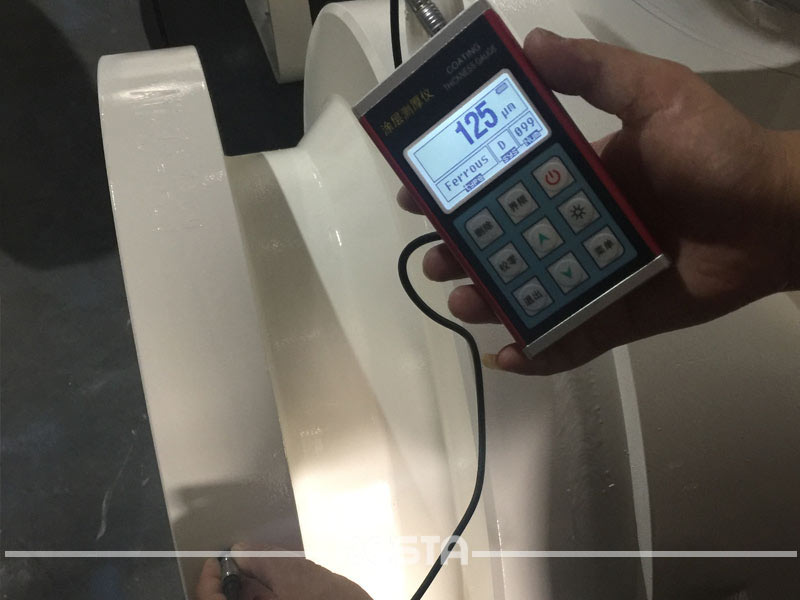

- Paint dry film thickness and adhesion inspection

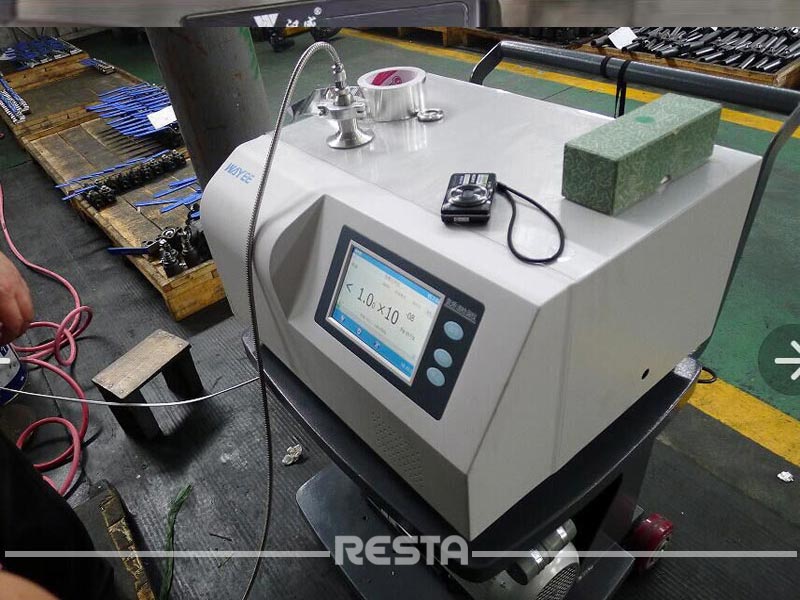

- Fugitive Emission Test

- Cryogenic Test

- HIC & SSCC test