ORBIT BALL VALVE

ORBIT BALL VALVE

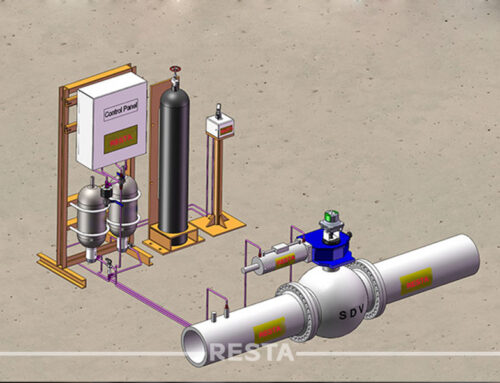

RESTA has developed new products-Orbit ball valve. The principle of cam makes the valve ball separate from the sealing surface of the valve seat during rotation. After rotating in place, push the valve ball to the valve seat to realize sealing. When the valve is in the fully open position, turn the hand wheel in an instant. With the cooperation of the valve stem nut and the thrust bearing, the valve stem begins to fall and drive the ball to rotate. The precision spiral curve groove track on the valve rod interacts with the guide pin embedded in it to drive the ball to rotate clockwise with the valve rod. When the valve is about to close, the valve stem drives the ball to rotate 90 ° without friction with the sealing surface of the valve seat. Continue to rotate the hand wheel, and the falling valve rod mechanically presses the ball through the cam structure at the lower end of the valve rod, so that the sealing surface of the ball is in close contact with the sealing surface of the valve seat, so as to achieve the purpose of sealing. When the track hard seal ball valve is in the fully closed position, turn the hand wheel counterclockwise. With the cooperation of the valve stem nut and the thrust bearing, the valve stem begins to rise and drive the ball to rotate,. By continuously rotating the hand wheel, the valve rod will drive the ball towards the valve seat while rising. When the track hard seal ball valve is about to open, the precise spiral curve groove track on the valve stem interacts with the guide pin embedded therein to drive the ball to rotate counterclockwise without friction with the sealing surface of the valve seat. Continue to rotate the hand wheel. When the valve stem rises to the limit position, the ball has also reversed 90 ° with the valve stem, and the valve is in the fully open position. Structural features of track hard seal ball valve: the traditional ball valve, whether floating or fixed, always contacts the ball and valve seat, with large switching torque and easy damage to the sealing surface. When the track ball is opened and closed, the ball deflects first- δ Angle, and then rotate. In the whole process of switching, the ball is separated from the valve seat, so the valve seat will not be scratched, and the opening and closing torque is small

1. There is no friction between opening and closing. This function completely solves the problem that the sealing surface of traditional valves is affected by mutual friction between sealing surfaces.

2. Top mounted structure. The valve installed on the pipeline can be directly inspected and repaired online, which can effectively reduce the shutdown of the device and reduce the cost.

3. Single seat design. The problem that the medium in the cavity of the valve affects the use safety due to abnormal pressure rise is eliminated.

4. Low torque design. The valve stem with special structure design can be opened and closed easily with only a small hand wheel.

5. Wedge seal structure. The valve is sealed by pressing the ball wedge onto the valve seat by the mechanical force provided by the valve stem, so that the tightness of the valve is not affected by the change of pipeline differential pressure, and the sealing performance is reliably guaranteed under various working conditions.

6. Self cleaning structure of sealing surface. When the ball tilts away from the valve seat, the fluid in the pipeline passes through the sealing surface of the ball at 360 °, which not only eliminates the local scouring of the valve seat by the high-speed fluid, but also washes away the accumulation on the sealing surface, so as to achieve the purpose of self-cleaning.